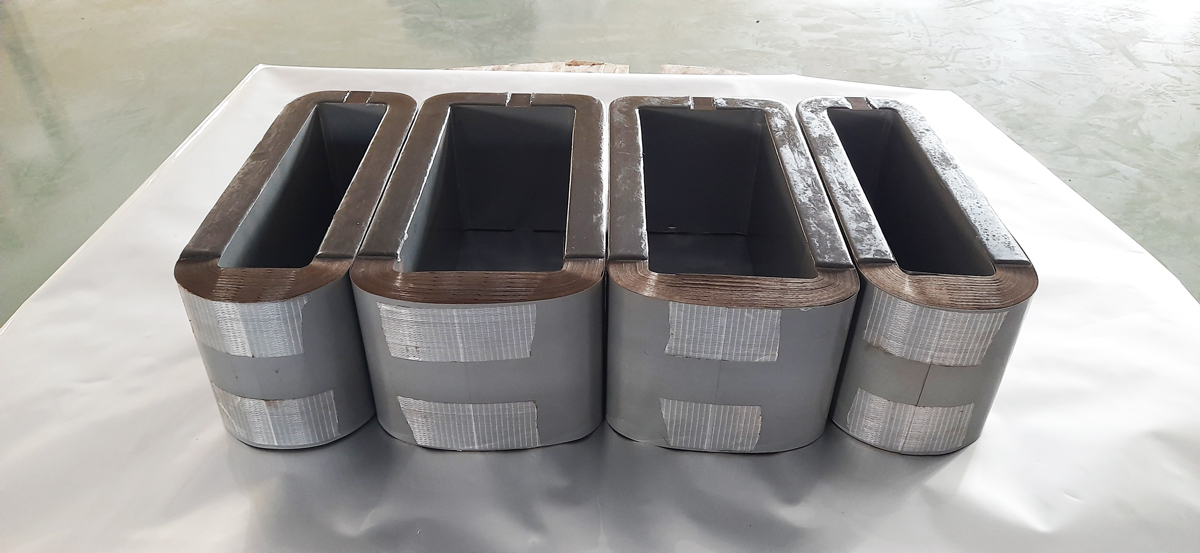

Amorphous Cores

KRYFS manufactures & supplies high quality, low loss core loops for both 1-Phase and 3-Phase distribution transformers.

KRYFS manufactures & supplies high quality low loss amorphous core loops for both 1-Phase and 3-Phase distribution transformer as per customer’s specification by using amorphous metal imported from prominent source.

The amorphous metal transformers are manufactured from core made with Fe-based amorphous ribbon. Amorphous ribbon is made up of mainly Iron, with small percentages of Silicon and Boron (Fe78, B13, and Si9) by fast quenching of molten metal at a rate of 106 deg per second. This is achieved by restricting the thickness of the ribbon to 25micron.

Random molecular structure of amorphous alloy eases magnetization and demagnetization result in lower hysteresis losses which in turn reduce energy consumption when a core is energized. Amorphous metal transformers are made from amorphous ribbon with 10 time’s thinner laminations as compared to conventional grade resulting in lower eddy current losses.

Distribution transformers are required to have low no-load losses as they are energized round the clock. Amorphous core transformers play an important role in reducing no-load losses Amorphous metal core transformers improve electrical power distribution efficiency by reducing transformer core losses. The loss reduction ranges from 65 to 80 % over CRGO based transformers. These efficiency improvements result in reduced power generation that is accompanied by reduced emission of environmentally sensitive gases such as CO2, SO2, etc; the total owing cost of utilities also reduces.

Always Putting Values Above Business

Basic Characteristics of Amorphous Metal Alloy

- The amorphous alloy has a saturation flux density of 1.56T with working flux density up to 1.4T

- The density of amorphous material is 7.18 gm/cc

- The thickness of the amorphous ribbon is 0.025 mm

- Lamination factor of 86%

- The specific core loss of amorphous metal is 0.1-0.2 watt/kg at 1.4 T

- Available in a standard width of 142 mm, 170 mm and 213 mm

- Need annealing at 340-360 deg C

Advantages of Amorphous Metal Transformer

70% lower losses as compared to conventional grade.

Low hysteresis & eddy current losses due to high magnetic permeability and reduced thickness of raw material

Better overload capacity as heat generation is less due to lower core loss

Environment friendly, reduces CO2 emission due to lower demand in generation

Low total cost of owning

Increased short circuit strength due to wound type construction

Core coil assembly is easy to assemble & repair

No load loss comparison (1-Ph Transformer)

| Rating | Amorphous Core Transformer (w) | CRGO Core Transformer (w) |

| 5 kVA | 8 | 22 |

| 10 kVA | 13 | 34 |

| 25 kVA | 25 | 60 |

No load loss comparison (3-Ph Transformer)

| Rating | Amorphous Core Transformer (w) | CRGO Core Transformer (w) |

| 5 kVA | 8 | 22 |

| 16 kVA | 18 | 34 |

| 25 kVA | 25 | 60 |

| 63 kVA | 58 | 170 |

| 100 kVA | 78 | 214 |

Download our Brochures Here

Download the offline version of all our offerings, feel free to contact us for any queries

Our Other Business

CRGO Lamination

CRGO Core Assembly

KRYFS Transformers

Amorphous Cores

Stringing Tools

EPC Projects

Rooftop Solar

BOLA - IoT System

Transformer Tanks

Material Handling