BOLA – An IoT based distribution transformer monitoring solution (DTMS)

Around 20% of distribution transformers fail every year in India, compared to 2 – 3% in developed countries.

WHY DO TRANSFORMERS FAIL?

Insulation

Failure

Fire or

Explosion

Moisture

Ingress

Over

Loading

Oil

Decay

Improper

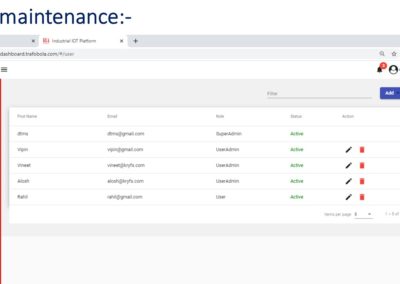

Maintenance

Line

Surges

Improper

System

Can this be avoided?

The answer is YES; most of these can be avoided with proactive monitoring and maintenance. Then why are these failures not prevented?

current practice of manual monitoring involves…

Maintenance staff to consistently monitor

Manual recording of data

MAINTENANCE IS DONE AT THE SCHEDULED TIME

NO ANALYTICS FROM DATA

INFORMATION IS NOT RECORDER AND ACCESSIBLE

However

Every important parameter cannot be monitored

No transparency and accuracy in recording data

Maintenance not baseed on real time condition of transformer

Data doesn’t give insights on corrective action to be taken

Right data may not be available to right people

Introducing BOLA

BOLA, our IoT based low-cost Distribution Transformer Remote Monitoring and Diagnosis solution, it monitors the transformer’s vital parameters online from any location in real-time. It will diagnose & amp; send alerts/notifications which you will receive on a Laptop or Phone whenever there is any abnormality sensed in the transformer. This allows maintenance to be scheduled and corrective action to be taken before the failure actually happens. The risk of failure is reduced using alarm rules and detection of deviation from a reference value or threshold (e.g., oil and winding temperature).

OVERLOAD PROTECTION

• Voltage, Current, Frequency

• Active Power, Apparent Power

• Unbalanced Loading, PF

COOLING PROTECTION

• Low & High Oil Level

• Ambient Temperature

THERMAL PROTECTION

• Oil Temperature

• Winding Hotspot Temperature

OTHERS

• Ambient Humidity

• GPS Location

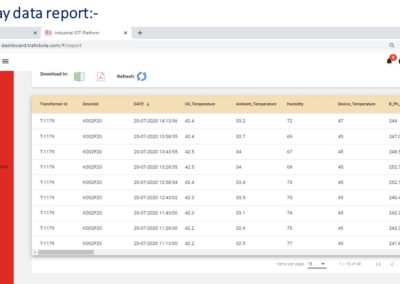

Remote monitoring of 3-phase currents, oil temperature, winding temperature, oil level, harmonics, etc.

Alarm on overload, unbalanced loading, low power factor, low oil level, high oil temperature, etc.

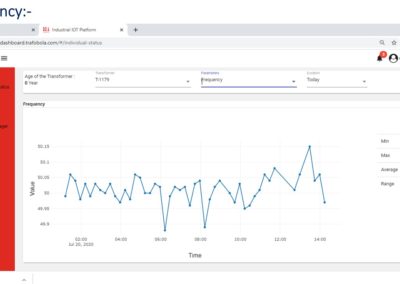

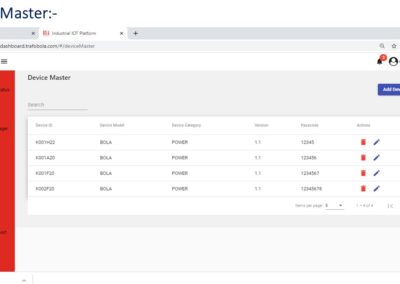

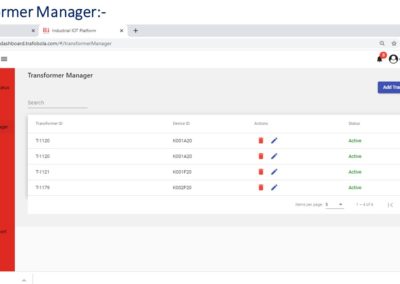

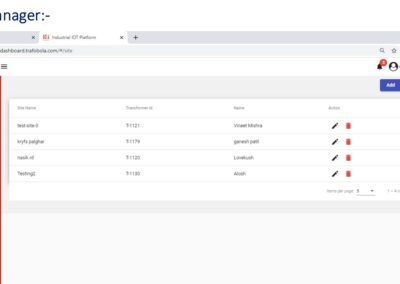

Real time monitoring of all parameters & graphical display with dashboards, acts as asset register.

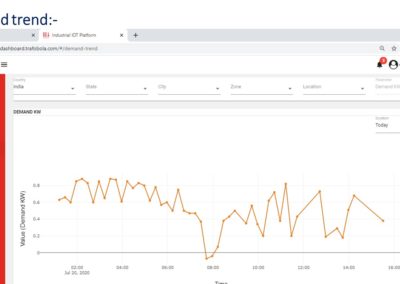

Demand variation insights, email & message notifications, tampering

notifications

How BOLA works

Bola, our IoT based Distribution Transformer Monitoring Solution (DTMS) works by collecting real-time data from the transformer with the help of sensors and sends it to the cloud via a sim card. It’s a condition-based transformer monitoring solution- Data supported maintenance as and when required.

BOLA Detects & Protects

Increased

Reliability

Asset

Register

Reduced

Ageing

Higher

Uptime

No Human

Error

Better

Management

Reduced

Maintenance

Delayed

Replacement

Real Time

Alerts

Downtime

Analysis

Increased

Reliability

Asset

Register

No Human

Error

Delayed

Replacement

Downtime

Analysis

Reduced

Ageing

Higher

Uptime

Better

Management

Reduced

Maintenance

Real Time

Alerts

“In God we trust; all others must bring data.”

W.Edward Deming

Our Case Studies

Download BOLA Brochure Here

Download the offline version of all our offerings in IoT business, feel free to contact us for any queries.

Our Other Business

CRGO Lamination

CRGO Core Assembly

KRYFS Transformers

Amorphous Cores

Stringing Tools

EPC Projects

Rooftop Solar

BOLA - IoT System

Transformer Tanks

Material Handling